Shipping containers were an incredibly important invention that changed the way goods would be exchanged forever. Invented in 1956, shipping containers made it possible to obtain cheap goods from across the world when prior to that time it was a rare anomaly.

Needless to say, here at Container Alliance we think shipping containers are pretty cool. They’re versatile, convenient, cost-efficient, and reliable. So I’m here to tell you how this game-changing invention is made.

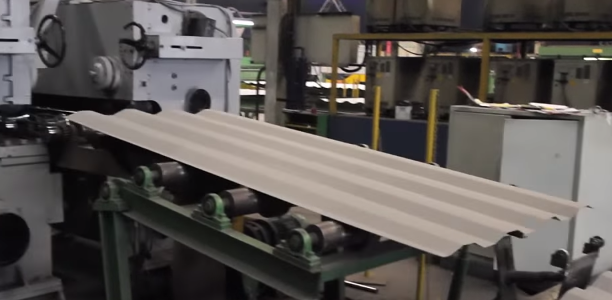

Step 1. Wall Panels

Shipping containers start out with large sheets of steel that are cut to specific dimensions by advanced machinery in a factory. Workers prepare the surface of the steel sheets by sandblasting and priming to ensure a clean finish before corrugating the sheets to strengthen them. The floor and roof panels are made separately. Then side wall panels are welded together to create the walls and square tubing is welded to the top of the walls.

Step 2. Floor Frame

Next, the floor frame is assembled with the prepared floor panels and welded on top of steel beams then sanded to remove any rough spots.

Step 3. Doors and Corner Posts

The doors are made similarly to the side walls. They start out with corrugated steel, then are encased with square steel tubing, sandblasted, and welded on the floor frame. The corner posts are welded into the floor frame beams next to the doors.

Step 4. Roof Panel

Once the door frame is welded into place, the roof panel is lowered onto the top of the frame and welded on, completing the shape of the container.

Step 5. Prime and Paint

The container is then sprayed with the first layer of primer to add protection and make the paint stick better. The paint is then sprayed onto the container in several layers once the primer has dried. The primer and paint protect the containers against harsh weather elements and travel across the sea.

Step 6. Floor Finishing

Wooden frames are varnished with a protective coating and installed into the floor, then drilled into the floor panels.

Step 7. Door Finish

The door hardware and rubber seals are installed to ensure watertight doors.

Step 8. Testing

Finally, the bottom of the container is tested and sealed to be waterproof. The finished container is tested for water tightness and any other problems.

After the long process of making such a durable and weather resistant steel container, the shipping containers are then put onto ships and sailed across the seas to us. One trip containers are named after this procedure and are a direct result of the steps taken above. Contact us if you want to get a hold of one of these!

Images Source: Container Home Plans